Want to read a paper that dives deeper?

Our Heat Treatment Process

ShapeEndo’s™ proprietary heat treatment technology transforms ordinary nickel-titanium into superior endodontic instruments that redefine the shaping potential of the instrument.

Why Heat Treatment Matters

Nickel-titanium (NiTi) alloys possess unique properties that make them ideal for endodontic instruments. However, raw NiTi requires precise heat treatment to unlock its full potential.

Our proprietary heat treatment process transforms the molecular structure of the alloy, creating instruments with enhanced flexibility, superior fatigue resistance, and optimal cutting efficiency.

500°C+

Peak treatment temperature

The ShapeEndo™ Heat Treatment Process

Initial Forming

Raw nickel-titanium wire is precisely machined into the desired file geometry using advanced CNC technology.

TEMPERATURE

Room Temperature

DURATION

Varies by file complexity

Pre-Heat Treatment

Files undergo initial thermal conditioning to prepare the alloy structure for the main heat treatment cycle.

TEMPERATURE

400°C – 500°C

DURATION

15-30 minutes

Primary Heat Treatment

Controlled heating in a specialized furnace transforms the crystalline structure of the nickel-titanium alloy.

TEMPERATURE

500°C – 550°C

DURATION

5-15 minutes

Rapid Cooling

Immediate quenching locks in the desired metallurgical properties and prevents unwanted phase transformations.

TEMPERATURE

Rapid cooling to <100°C

DURATION

30-60 seconds

Tempering

Secondary heat treatment optimizes the balance between flexibility and strength for clinical performance.

TEMPERATURE

300°C – 400°C

DURATION

10-20 minutes

Quality Control

Each batch undergoes rigorous testing for flexibility, fatigue resistance, and cutting efficiency.

TEMPERATURE

Room Temperature

DURATION

Comprehensive testing

The Science Behind Heat Treatment

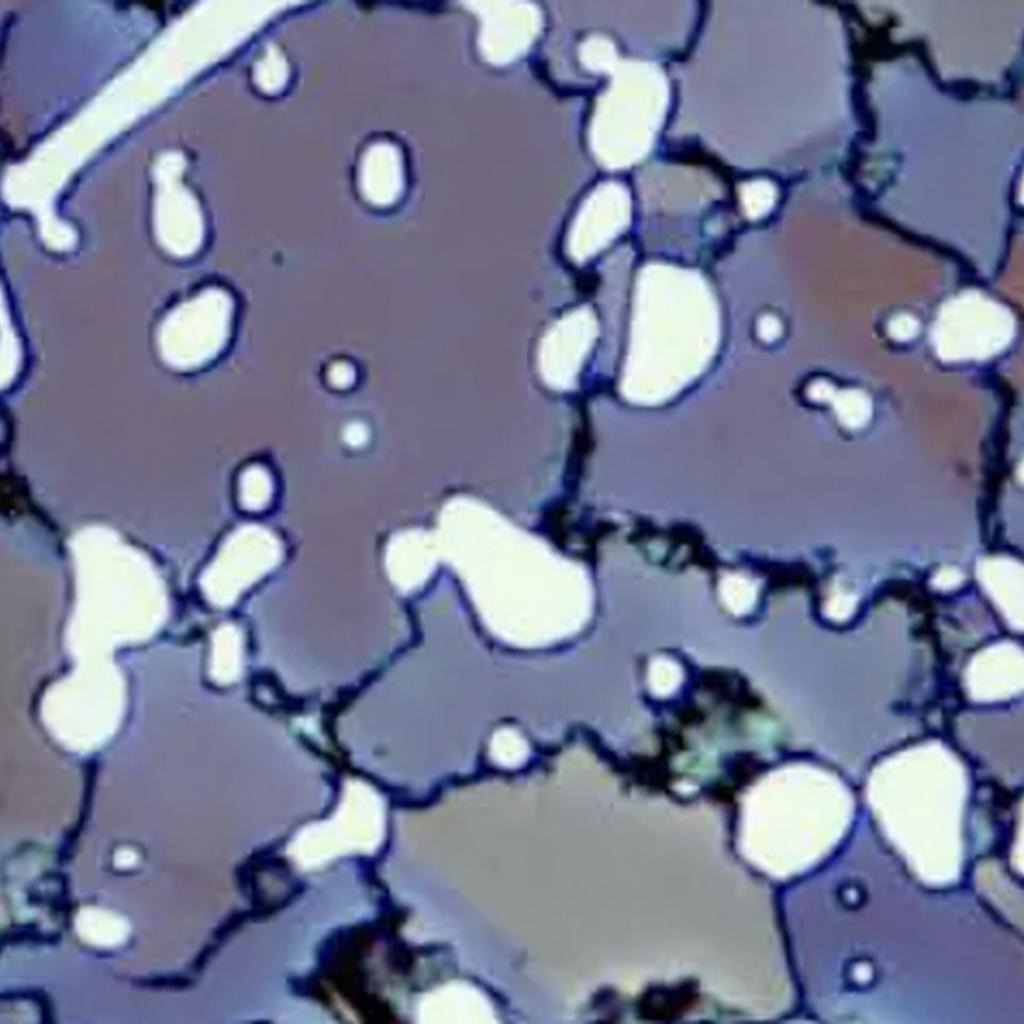

Martensitic Transformation

Heat treatment controls the martensitic transformation temperature of NiTi alloys. This transformation is responsible for the superelastic behavior that allows files to bend significantly without permanent deformation.

Grain Structure Optimization

Controlled heating and cooling refines the grain structure of the alloy, eliminating stress concentrations and improving the overall mechanical properties of the finished instrument.

Residual Stress Relief

The heat treatment process eliminates residual stresses introduced during manufacturing, preventing premature failure and extending the service life of the instruments.

Surface Optimization

Precise temperature control creates an optimal surface finish that enhances cutting efficiency while reducing friction during clinical use.

Clinical Benefits of Heat Treatment

Enhanced Flexibility

Heat treatment transforms the molecular structure of nickel-titanium, creating files that can navigate curved canals with unprecedented flexibility while maintaining their original shape.

Increased Fatigue Resistance

The controlled heating and cooling process significantly improves the file’s resistance to cyclic fatigue, reducing the risk of instrument separation during clinical use.

Superior Cutting Efficiency

Heat-treated files maintain their cutting edge longer and provide more efficient dentin removal, resulting in faster and more predictable procedures.

Optimal Memory Properties

The heat treatment process enhances the superelastic properties of NiTi, allowing files to return to their pre-determined shape after deformation.